For the auxiliary and protection system for the plant, they need supplies to be in 6.6kV/AC, 415V/AC, 220V/DC, 24V/DC and 220V/AC. All this supply will come from the generation of the plant it’s own. Therefore it needs the switchgear system to arrange and distribute all the supply to the devices accordingly.

This switchgear system also connected to the black start diesel and emergency diesel generators. These two generators are used when there are emergencies like system trip or suddenly lost of supply. During these situations, the emergency generator will automatically cut in and supply 415V to the 415V feeder bus, and the operator will need to manually switch on the black start diesel generator manually to supply 6.6kV to the feeder.

Sunday, June 6, 2010

GT and ST single line diagram

Before going into detail of electrical knowledge, the basic flow of this plant is necessary for us to study. The first drawing that we are exposed to is the single line diagram of Gas turbine generator and steam turbine generator.

For both gas turbine and steam turbine generator single line diagram, they are having the same concept of electrical flow. First the generated power is 10.5kV which will be stepped up to 275kV then send to national grid. At the same time, the generated voltage will then stepped down for the excitation system and the gas turbine control supply.

Later this single line diagram will be further connected to the switchgear drawing and switchyard connection.

For both gas turbine and steam turbine generator single line diagram, they are having the same concept of electrical flow. First the generated power is 10.5kV which will be stepped up to 275kV then send to national grid. At the same time, the generated voltage will then stepped down for the excitation system and the gas turbine control supply.

Later this single line diagram will be further connected to the switchgear drawing and switchyard connection.

Electrical Department

Entering the seventh week of training (16 MAY 2010), I am now in the electrical department. Being the first day in this department, everything seems to be nice. The manager and engineer are friendly and willing to share knowledge to us. Since I am an electrical power student, I can’t wait to learn the practical things about my course.

.JPG)

.JPG)

Firstly we are asked to follow the workers to the workshop, and luckily during the first day we already had the opportunity to follow the workers for a switchgear and motor maintenance. This maintenance is taken to make check the motor supply balancing, the insulation of the connection and also the physical neatness of the motor and switchgear.

Firstly we are asked to follow the workers to the workshop, and luckily during the first day we already had the opportunity to follow the workers for a switchgear and motor maintenance. This maintenance is taken to make check the motor supply balancing, the insulation of the connection and also the physical neatness of the motor and switchgear.

Saturday, May 22, 2010

Measurement and analysis

Since I enter the Control and Instrumental department, I had a lot of opportunity to learn about measurement instrument. All these instruments are used to measure temperature, pressure, mass flow rate, volume flow rate, level, filter clog and so on.

First I want to introduce about RTD, resistance temperature detector. It is used to measure temperature with the concept “relationship between resistance and temperature”. Both of these parameters are in proportional, which means, the higher the temperature, the higher the resistance.

Another temperature measurement instrument is thermocouple. It used the seebeck effect to build this instrument where it uses two different metals which bonded together. When the hot junction of the metal is being exposed to certain temperature, voltage will be produced.

On the other hand, other than measuring temperature, we need to measure pressure too. Instrument normally used is differential pressure transmitter. Other then measuring pressure, this instrument can be used to measure level and filter clog too.

Other then all that I mention before this, there are still many transducer that I learned. It’s been a great experience to be in this control and instrumental department, however, my training had almost come to the sixth week. Next week I am going to transfer to electrical department. At here, I wish to thanks to all staffs in this department that had taught me a lot during these six weeks, especially, our “Tok Guru”, Mr. Tawang.

First I want to introduce about RTD, resistance temperature detector. It is used to measure temperature with the concept “relationship between resistance and temperature”. Both of these parameters are in proportional, which means, the higher the temperature, the higher the resistance.

Another temperature measurement instrument is thermocouple. It used the seebeck effect to build this instrument where it uses two different metals which bonded together. When the hot junction of the metal is being exposed to certain temperature, voltage will be produced.

On the other hand, other than measuring temperature, we need to measure pressure too. Instrument normally used is differential pressure transmitter. Other then measuring pressure, this instrument can be used to measure level and filter clog too.

Other then all that I mention before this, there are still many transducer that I learned. It’s been a great experience to be in this control and instrumental department, however, my training had almost come to the sixth week. Next week I am going to transfer to electrical department. At here, I wish to thanks to all staffs in this department that had taught me a lot during these six weeks, especially, our “Tok Guru”, Mr. Tawang.

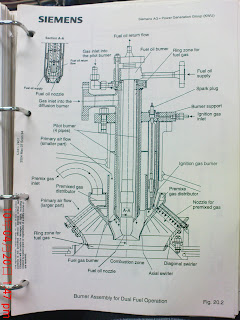

Combustion chamber ball valve operation sequence

Today I learn about ball valve operation sequence which located at the combustion chamber. These ball valves control the amount and the flow of the fuel gas flow into the burner inside the combustion chamber. There are three different modes in the burner. They are diffusion, premix and pilot valve.

For diffusion mode, the fire flame is yellow colour, produce No and Co, burn stable and not complete burning. Premix mode, the fire flame is blue colour, produce less pollution, burn unstable and complete burning. Beside that, pilot node is used to help premix mode to burn in a higher stability.

Because of all these characteristic, diffusion mode is used during start up and shut down of the combustion chamber, while premix and pilot mode are used during normal operation of the combustion chamber.

For diffusion mode, the fire flame is yellow colour, produce No and Co, burn stable and not complete burning. Premix mode, the fire flame is blue colour, produce less pollution, burn unstable and complete burning. Beside that, pilot node is used to help premix mode to burn in a higher stability.

Because of all these characteristic, diffusion mode is used during start up and shut down of the combustion chamber, while premix and pilot mode are used during normal operation of the combustion chamber.

Friday, May 14, 2010

Hardware and Software

After several days training in C&I department, I observe that every time when the engineer going to work, they will bring some kind of drawing which I don’t really understand. Fortunately, Mr. Tawang gave us some introduction about it today. During the design of this plant’s control and instrumental system, they need to have the hardware and software drawing since this system is very complicated. For hardware drawing it explain about the type of transducer, the connection from field to control room, the location and so on. Workers need it to understand the construction of the instrument that they are going to deal with.

On the other hand, software drawing is the digital logic which connected to a particular transducer. These drawing explain the open loop control, close loop control and protection of the instrument.

All this drawings are kept in tick files in the library which I found very interesting. I wish I could explore more about it in the future.

On the other hand, software drawing is the digital logic which connected to a particular transducer. These drawing explain the open loop control, close loop control and protection of the instrument.

All this drawings are kept in tick files in the library which I found very interesting. I wish I could explore more about it in the future.

C&I Structure

So far, I had gone to control room and PCC. These places had a lot of cabinet which control the plant. Today, I had the chance to learn about details of the control and instrumental structure.

The operation condition of the plant is important for the operator to monitor it from time to time, therefore, transducers or sensors like magnetic flowmeter, DP transmitter, RTD, thermocouple, and so on, are connected to every machines in the plant. All these transducers then will convert the paramenters like temperature, pressure, flow rate and so on, into electrical form, then sent it to a card in a cabinet which called the ET 200. Later it will send to PCC automation cabinet, then the data will pass into fiber optic cable and transmit to control room’s busses cabinet. After passing through several server, data will then send to computer to display. This is the general idea of how the data is being processed.

After knowing all this, I realize that, to design a control and instrumental structure is very complicated and it involve a lot of knowledge like mechanical, micro p, digital logic, and so on. This is a good experience for me to know the application of my knowledge learn during university.

DC to DC converter faulty

Another fault notification this morning, I had the opportunity to join the investigation. I followed Mr. Sabrin and Mr. Muzammil to the field. After some investigation, they discovered that the DC to DC converter had some problem. Action to be taken is to replace the converter with a new one. Maybe you will asked, what is the effect of this fault? Actually, there are two DC to DC converters which backup for each other, therefore, even one of the converters doesn’t function, the other one will take over, so, there doesn’t affect the system. This is actually the protection design in this plant.

Performing this job actually needs to be very careful since a single mistake can cause huge unwanted effect like tripping the system. Therefore, there are many precaution procedure need to be taken. Firstly, before performing the task, the particular circuit breaker needs to be disconnected to make sure there are no supplied to the converter, reconfirm which wire to be unplugged and so on.

From the experience today, I realize the important of hardware drawings and software drawings which store in the tick files in library. Finally, I got the opportunity to deal with it, and hopefully I can learn more details in the future.

Performing this job actually needs to be very careful since a single mistake can cause huge unwanted effect like tripping the system. Therefore, there are many precaution procedure need to be taken. Firstly, before performing the task, the particular circuit breaker needs to be disconnected to make sure there are no supplied to the converter, reconfirm which wire to be unplugged and so on.

From the experience today, I realize the important of hardware drawings and software drawings which store in the tick files in library. Finally, I got the opportunity to deal with it, and hopefully I can learn more details in the future.

Friday, May 7, 2010

Another Calibration

Yesterday we learn about pressure transducer calibration, today we had the opportunity to do another one. This pressure transducer is different with the one before, it is a mechanical instrument which called c-bourdon. It used the concept just like the party favor, when the pressure enter the c-bourdon, it will try to straighten out, as a result, it will pull the pointer to the correct scale.

.JPG)

what the engineer do today is to calibrate the pressure transducer. Similarly, engineer attach the handpump and multifuntional calibrator together, and inject pressure. Multifunctional calibrator as reference, they check the scale of c-bourdon. Adjustment is done when necessary.

.JPG)

The c-bourdon shows some error reading, after some maintenance, the error is acceptable. lastly, they attach back the pressure transducer back to the turbine.

what the engineer do today is to calibrate the pressure transducer. Similarly, engineer attach the handpump and multifuntional calibrator together, and inject pressure. Multifunctional calibrator as reference, they check the scale of c-bourdon. Adjustment is done when necessary.

The c-bourdon shows some error reading, after some maintenance, the error is acceptable. lastly, they attach back the pressure transducer back to the turbine.

Friday, April 23, 2010

First Side working involvement

After getting the safety equipment, finally we are allow to follow the engineers to work at the side. This time is a 21MBR10CP calibration (pressure transducer calibration). According to the engineers, the pressure transducer calibration need to be checked at least once a year to make sure the pressure transducer's switch is able to disconnect at the correct pressure, 50mbar.

The engineers unplug the pressure transducer and inject pressure to it. Later, they check the disconnect pressure and adjust it to the correct scale. There are three transducers that need to be checked, after watching the engineers doing that, they allow us to hands on for the last transducer, and this is a precious opportunity for me to learn and experience. After checking all three transducers, they attach them back to the machine.

.JPG)

After performing all this work, we go back to the control room, the engineers explain to us that the function of the transducer. They are used for the 2 out of 3 protection system, which means, if two of them show high pressure, the system will trip on its own.

.JPG)

This is what we learn during this calibration check out and we are very lucky to have mr. Tawang who are willing to teach us.

The engineers unplug the pressure transducer and inject pressure to it. Later, they check the disconnect pressure and adjust it to the correct scale. There are three transducers that need to be checked, after watching the engineers doing that, they allow us to hands on for the last transducer, and this is a precious opportunity for me to learn and experience. After checking all three transducers, they attach them back to the machine.

After performing all this work, we go back to the control room, the engineers explain to us that the function of the transducer. They are used for the 2 out of 3 protection system, which means, if two of them show high pressure, the system will trip on its own.

This is what we learn during this calibration check out and we are very lucky to have mr. Tawang who are willing to teach us.

Wednesday, April 14, 2010

Safety and Health Precaution

Working in YTL power plant which is consider to be a dangerous working place, it is important that everyone taken the safety precaution well to protect ourselves and also others. During the safety briefing, we were informed that to :

1. Wear PPE when we are working in the power plant.

2. Follow the safety precaution when performing certain job.

3. Require a permit before performing any job.

.JPG)

Safety shoes

.JPG)

Safety helmet

.JPG)

Ear plug

Everyone of the trainee are provided these safety equipment and attire that we need once we enter the power plant. Thanks to YTL Power.

1. Wear PPE when we are working in the power plant.

2. Follow the safety precaution when performing certain job.

3. Require a permit before performing any job.

Safety shoes

Safety helmet

Ear plug

Everyone of the trainee are provided these safety equipment and attire that we need once we enter the power plant. Thanks to YTL Power.

Friday, April 9, 2010

Basic Plant Operation

During the first week of industrial training, we had went through the basic operation of the plant. From the input resource (natural gas) until the production (electrical power),this proses is done by a power plant system from SIEMENS v94.2.

GAS TURBINE PLANT:

Natural gas are feed into the gas turbine to generate the first stage power where te rated ISO-power is 150 MW. The siemens V94.2 gas turbine generator are single shaft, single casing and heavy duty design.

HEAT RECOVERY STEAM GENERATOR (HRSG):

For combine cycle system design, the heat produce in the gas turbine is not wasted, where it is used to heat up water to superheated steam to supply it to the second generation stage, steam turbine generation.

STEAM, FEEDWATER AND CONDENSATE PLANT

The drum of each HRSG is supplied with feedwater from the feedwater tank by means of HP feedwater pumps. This feedwater will go through four stage of heating process, they are preheater, economizer, evaporator and superheater.

The superheated steam produce will be sent to the steam turbine via the main steam piping system.

STEAM TURBINE GENERATOR

The steam turbine is designed as a single-casing, axial-flow reaction condensing turbine. When it was supplied with superheated steam, power will be generated. Later, the superheated steam will release its energy and back to steam, and this steam will be cooled down by seawater and recycle back to the boiler stack to heat up again.

Above are the discussion of the basic operation of YTL power plant. The power produce in both gas turbine generator and steam turbine generator, will be gathered and send to TNB for further distribution.

GAS TURBINE PLANT:

Natural gas are feed into the gas turbine to generate the first stage power where te rated ISO-power is 150 MW. The siemens V94.2 gas turbine generator are single shaft, single casing and heavy duty design.

HEAT RECOVERY STEAM GENERATOR (HRSG):

For combine cycle system design, the heat produce in the gas turbine is not wasted, where it is used to heat up water to superheated steam to supply it to the second generation stage, steam turbine generation.

STEAM, FEEDWATER AND CONDENSATE PLANT

The drum of each HRSG is supplied with feedwater from the feedwater tank by means of HP feedwater pumps. This feedwater will go through four stage of heating process, they are preheater, economizer, evaporator and superheater.

The superheated steam produce will be sent to the steam turbine via the main steam piping system.

STEAM TURBINE GENERATOR

The steam turbine is designed as a single-casing, axial-flow reaction condensing turbine. When it was supplied with superheated steam, power will be generated. Later, the superheated steam will release its energy and back to steam, and this steam will be cooled down by seawater and recycle back to the boiler stack to heat up again.

Above are the discussion of the basic operation of YTL power plant. The power produce in both gas turbine generator and steam turbine generator, will be gathered and send to TNB for further distribution.

Wednesday, April 7, 2010

INTRODUCTION

This is the first article for my industrial training blog, so i think i need to do some introduction to the place that the training take place.

Location:

Paka YTL Power Station

Department:

5 weeks in control and instrumental department

5 weeks in electrical department

2 weeks in operation department

Training duration:

5 April 2010 till 25 June 2010

YTL power station is a power plant that consist of 2 combine cycle block. It has a capacity of 808 MW where it means that the station maximum production is 808 MW, but the station will not always stress the machine to perform its maximum rate, normally, it produce around 780 MW plus depends on the schedule. The power that generated by Paka YTL Power Station, will be supply to TNB Sultan Ismail power station where locate just beside YTL power plant. The resource of this power station is natural gas that directly supplied from PETRONAS.

The advantage of combine cycle power plant:

- highest efficiency

- best economy

- greatest flexibility

- fastest installation

- least pollution

Subscribe to:

Posts (Atom)